main

7 Reasons Pottery Cracks and How to Prevent Them | Important Tips

Are you wondering what causes cracks in pottery, why they happen, and how to prevent them? You are at the right place to get answers to these questions.

When you consider buying a pottery wheel, the pottery’s susceptibility to cracks may stop your mind. There are many reasons why pottery cracks, but the popular cause is uneven clay drying during production, making some clay parts shrink more than others. Hence, to avoid pottery cracks, you should ensure that the entire piece dries at a similar rate.

But that’s not all! Aside from uneven firing, there are other reasons why pottery crack. So, without further ado, the article will give you great insight into why they happen and how you can prevent them. So, read on to avoid losing your pottery to cracks.

Clay contains a lot of water (20%) and tends to retain a lot of water. This is why clay takes time to dry. A structural strain occurs in your pottery piece when one part of the clay dries faster than other parts.

The larger the piece of pottery, the greater its susceptibility to cracking. This problem is because the pottery piece dries unevenly. In other words, the surface of the large pottery piece would dry faster than the inner layer.

So, how do you prevent this from happening? Ensure you turn the ware during the heating process to ensure all surface areas receive equal heat.

An alternative way is to heat your ware by placing the piece on a rack within the oven. This approach will ensure even drying as the ware gets heated by the airflow within the oven. Ensure you expose the ware to this form of heat for an extended period to guarantee optimal drying.

You should note that once pottery is dry, repairing a crack becomes a tad harder.

Clay contains a lot of water (20%) and tends to retain a lot of water. This is why clay takes time to dry. A structural strain occurs in your pottery piece when one part of the clay dries faster than other parts.

The larger the piece of pottery, the greater its susceptibility to cracking. This problem is because the pottery piece dries unevenly. In other words, the surface of the large pottery piece would dry faster than the inner layer.

So, how do you prevent this from happening? Ensure you turn the ware during the heating process to ensure all surface areas receive equal heat.

An alternative way is to heat your ware by placing the piece on a rack within the oven. This approach will ensure even drying as the ware gets heated by the airflow within the oven. Ensure you expose the ware to this form of heat for an extended period to guarantee optimal drying.

You should note that once pottery is dry, repairing a crack becomes a tad harder.

After molding the clay using a pottery wheel, firing is the next step in making beautiful pottery. But, when firing is done improperly, it usually cracks. So how do you fire evenly? By controlling the amount of heat, the ware receives and how long it receives the heat.

Using an electric-powered kiln for firing your pottery helps take care of the above challenges. The reason is that you can automatically control heat and duration.

After molding the clay using a pottery wheel, firing is the next step in making beautiful pottery. But, when firing is done improperly, it usually cracks. So how do you fire evenly? By controlling the amount of heat, the ware receives and how long it receives the heat.

Using an electric-powered kiln for firing your pottery helps take care of the above challenges. The reason is that you can automatically control heat and duration.

Insufficiently wedged clay would have varying levels of moisture, causing different densities of clay parts. Denser clay takes a longer time to dry than the less dense parts, resulting in uneven drying. To prevent this scenario, ensure you wedge your clay properly.

Insufficiently wedged clay would have varying levels of moisture, causing different densities of clay parts. Denser clay takes a longer time to dry than the less dense parts, resulting in uneven drying. To prevent this scenario, ensure you wedge your clay properly.

Joints in your pottery piece are often areas of weakness and also points of cracks. Scoring the joining parts and applying slip paints before joining helps eliminate the joint weakness.

Joints in your pottery piece are often areas of weakness and also points of cracks. Scoring the joining parts and applying slip paints before joining helps eliminate the joint weakness.

The best form of clay for making pottery contains a “grog.” Grog helps increase the pore spaces within clay particles. This increase in pore spaces makes it easier for moisture to come to the surface while making evaporation faster. Therefore, make sure you have a general idea of what clay to use for the pottery wheel before building pottery.

The best form of clay for making pottery contains a “grog.” Grog helps increase the pore spaces within clay particles. This increase in pore spaces makes it easier for moisture to come to the surface while making evaporation faster. Therefore, make sure you have a general idea of what clay to use for the pottery wheel before building pottery.

Covering your pottery helps you control how quickly it dries out. You could cover it using a plastic bag. The humidity of your environment should determine how you cover the ware. In areas of low humidity, you can leave the base of the bag open to increase airflow. But for high humidity, you can seal the bag to trap moisture within it.

Why Pottery Cracks Happen and How to Prevent Them

1. Uneven Pottery Drying

Clay contains a lot of water (20%) and tends to retain a lot of water. This is why clay takes time to dry. A structural strain occurs in your pottery piece when one part of the clay dries faster than other parts.

The larger the piece of pottery, the greater its susceptibility to cracking. This problem is because the pottery piece dries unevenly. In other words, the surface of the large pottery piece would dry faster than the inner layer.

So, how do you prevent this from happening? Ensure you turn the ware during the heating process to ensure all surface areas receive equal heat.

An alternative way is to heat your ware by placing the piece on a rack within the oven. This approach will ensure even drying as the ware gets heated by the airflow within the oven. Ensure you expose the ware to this form of heat for an extended period to guarantee optimal drying.

You should note that once pottery is dry, repairing a crack becomes a tad harder.

Clay contains a lot of water (20%) and tends to retain a lot of water. This is why clay takes time to dry. A structural strain occurs in your pottery piece when one part of the clay dries faster than other parts.

The larger the piece of pottery, the greater its susceptibility to cracking. This problem is because the pottery piece dries unevenly. In other words, the surface of the large pottery piece would dry faster than the inner layer.

So, how do you prevent this from happening? Ensure you turn the ware during the heating process to ensure all surface areas receive equal heat.

An alternative way is to heat your ware by placing the piece on a rack within the oven. This approach will ensure even drying as the ware gets heated by the airflow within the oven. Ensure you expose the ware to this form of heat for an extended period to guarantee optimal drying.

You should note that once pottery is dry, repairing a crack becomes a tad harder.

2. Insufficient Firing

After molding the clay using a pottery wheel, firing is the next step in making beautiful pottery. But, when firing is done improperly, it usually cracks. So how do you fire evenly? By controlling the amount of heat, the ware receives and how long it receives the heat.

Using an electric-powered kiln for firing your pottery helps take care of the above challenges. The reason is that you can automatically control heat and duration.

After molding the clay using a pottery wheel, firing is the next step in making beautiful pottery. But, when firing is done improperly, it usually cracks. So how do you fire evenly? By controlling the amount of heat, the ware receives and how long it receives the heat.

Using an electric-powered kiln for firing your pottery helps take care of the above challenges. The reason is that you can automatically control heat and duration.

3. Thickness and Design Complexity

Another reason why uneven firing occurs includes pottery thickness and the intricacy of pottery design. If different parts of your ware have an unequal thickness, there is a greater tendency for cracks to appear. Have you ever wondered why the base of pots and cases crack more often than the sides? The reason is that the base is usually thicker than the sides and takes a longer time to dry than the sides. So, how do you prevent this? Ensure that all parts of your pottery ware are of even thickness, either by using a measuring tool or using your eye observation. Design complexity is another reason why uneven firing could occur. Pottery with intricate designs tends to have uneven thickness. The lips and handles are often less thick than other parts, and cracks could occur due to the unevenness. So, how do you prevent this from happening? Ensure that your pottery designs are not too complex and have a similar thickness as other parts of the ware. If pottery thickness must be uneven, ensure you wax the less thick areas to reduce the rate of moisture loss.4. Clay Wedging

Insufficiently wedged clay would have varying levels of moisture, causing different densities of clay parts. Denser clay takes a longer time to dry than the less dense parts, resulting in uneven drying. To prevent this scenario, ensure you wedge your clay properly.

Insufficiently wedged clay would have varying levels of moisture, causing different densities of clay parts. Denser clay takes a longer time to dry than the less dense parts, resulting in uneven drying. To prevent this scenario, ensure you wedge your clay properly.

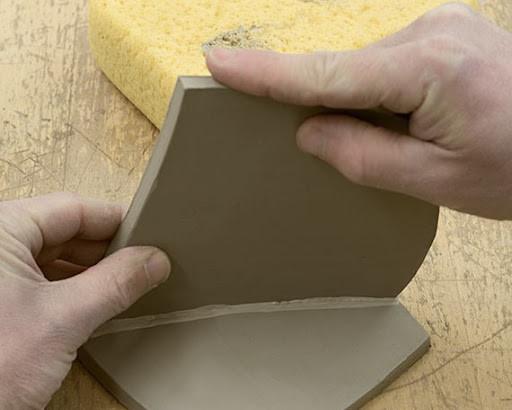

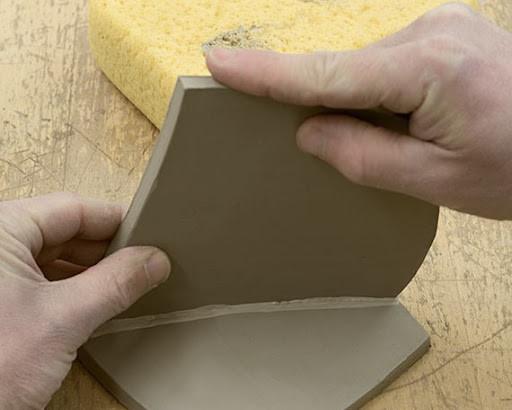

5. Pottery Joining Parts

Joints in your pottery piece are often areas of weakness and also points of cracks. Scoring the joining parts and applying slip paints before joining helps eliminate the joint weakness.

Joints in your pottery piece are often areas of weakness and also points of cracks. Scoring the joining parts and applying slip paints before joining helps eliminate the joint weakness.

6. Clay Type Used

The best form of clay for making pottery contains a “grog.” Grog helps increase the pore spaces within clay particles. This increase in pore spaces makes it easier for moisture to come to the surface while making evaporation faster. Therefore, make sure you have a general idea of what clay to use for the pottery wheel before building pottery.

The best form of clay for making pottery contains a “grog.” Grog helps increase the pore spaces within clay particles. This increase in pore spaces makes it easier for moisture to come to the surface while making evaporation faster. Therefore, make sure you have a general idea of what clay to use for the pottery wheel before building pottery.

7. Atmospheric Moisture Content

When there is little moisture in the atmosphere, the clay dries out quickly. This becomes a problem when it causes uneven drying of the clay piece. Also, if you place your pottery in areas with a high draft, cracking has a great tendency to occur. The reason is that draft makes the clay dry out quickly.Other Important Tips on How to Prevent Pottery Cracks

-

Cover Up with Plastic Bag

-

Shield The Fast Drying Areas

-

Turn Pottery Over During Drying

- It exposes the bottom of the pottery piece of air

- It protects the lip of the pottery from exposure to air, ensuring the lip dries at a similar rate to the other pottery parts.