BEST BOTTLE FILLING MACHINE COLLECTION FOR YOU

- Best Brands

Moonshan

BestEquip

Hanchen

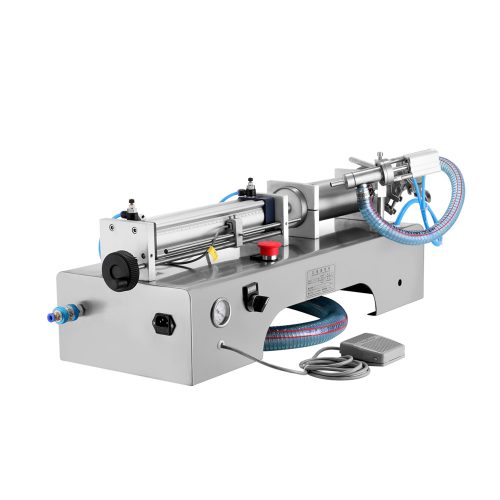

VEVOR

- Product details

Is it fluid or very dense? Different types of machines are suitable for different fillers. Piston machines are ideal for viscous liquids, while gravity machines are more suitable for thin, flowing liquids.

- Particles

If your product has particles, this can clog the nozzle of a gravity machine.

- Environment

In addition, pharmaceutical products require a sterile environment; chemical products require explosion-proof and flame retardant systems. There are strict rules for such products. Before buying a liquid filling machine, considering these is a must.

- Containers

- Degree of automation

Is a manual, semi-automatic or fully automatic machine right for you? Experts agree that a semi-automatic or manual bottle filling machine is a good choice for small batches. As production scales up, you may consider a fully automatic bottle filling machine to increase efficiency.

- Integration

- Accuracy

Automated filling machines bring accurate filling. This saves costs and reduces the time and expense spent on cleaning the machine.

A vacuum is suitable for liquids or powders that flow at low or medium speeds, such as wine, milk powder, etc.

Pressure is more suitable for medium and high-speed flow and carbonated liquids.

Gravity is suitable for non-carbonated beverages and different flow speeds.

- Liquid Filling Machine

- Manual liquid filling machines

- Semi-automatic liquid filling machines

- Fully automatic liquid filling machine

- Automatic volumetric linear filling machine

- Bottle Filling Machine

- Automatic bottle filling machine

- Semi-automatic bottle filling machine

- Volumetric liquid bottle filling machine

- Powder Filling Machine

- Auger Powder Filling Machine

- Capsule Filling Machine (pharmaceutical packaging)