Subtotal: $137.00

BEST BELT GRINDER COLLECTION FOR YOU

- Types

Bench Grinder

Belt Grinder

Wet Grinder

Die Grinder

Floor Grinder

- Belt size

Other options include:

1X42 belt grinder

2X42 belt grinder

2X48 belt grinder

4X36 belt grinder

1x30 belt grinder

- Motor size

- Belt speed

sfpm = (π x drive pulley diameter) x motor speed

- Variable speed

- The best brands:

WEN

3M

Palmgren

Jet

Grizzly Industrial

Work Sharp

Red Label Abrasives

Zivisk

Huanyu

DEWALT

EX ELECTRONIX EXPRESS

SPTA

C.S. Unitec

Bader

- Selecting a belt grinder

2x72 belt grinder

1X42 belt grinder

2X42 belt grinder

2X48 belt grinder

4X36 belt grinder (more suitable for woodworking than knife making)

- Sharpening process of knife-making

2. How to sharpen the bevel

3. Finishing the blade

Here is the website for reference.

https://www.redlabelabrasives.com/blogs/news/how-to-use-a-belt-grinder-for-knife-making

- Belt sander

If you are sanding wood, the wood will not burn because of the slower belt speed and the belt sander will not remove a ton of material at once, so you will have time to process the wood and get the finish you're looking for.

If you are sanding metal, you can quickly remove all sharp edges and rounded corners. Plus, you have only one area to sand around the table and platen. The lower pulley, or as we call it in our industry (the drive pulley because it drives the belt), is a hard plastic pulley that is unsuitable for sanding.

- Belt grinder

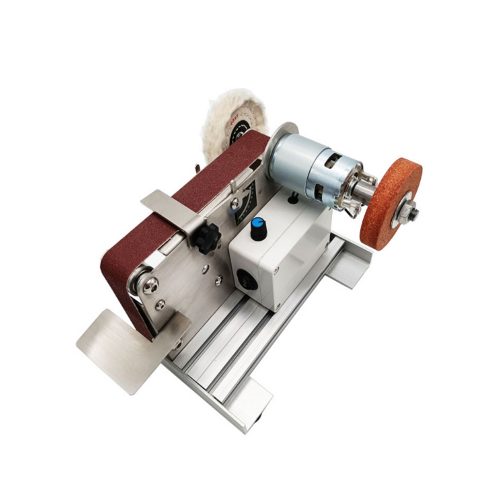

Belt grinders typically have multiple grinding points, such as a platen, with a second grinding point being the contact wheel.

- Homemade Belt Grinder Steps

Step 2: Fabrication and installation of front panel

Step 3: Making and installing the back panel

Step 4: Making the hinge for the tracking wheel

Step 5:Make the upper arm

Step 6: Making the feet

Step 7: Making the tool holder

Step 8: Making the flat tool arm

Step 9: Installing the gas spring for belt tension

Step 10: Troubleshooting

Step 11: Fully armed and operable belt grinder

Step 12: Updating the design

Here are some websites for reference. They have additional information that can help you to make a DIY 2x72 belt grinder.

https://www.instructables.com/2X72-Belt-Grinder/

http://dcknives.blogspot.com/p/2-x-72-belt-grinder.html

http://dcknives.blogspot.com/p/budget-2-x-72-belt-grinder-build.html

- Steps:

2. Choose the direction of rotation for your sander.

3. Turn the belt sander on to maximum speed.

4. Sharpen the blade.

5. Allow your knife to cool.

6. Hone the blade.

Here is the website for your reference.

https://www.knifeguides.com/how-to-sharpen-a-knife-using-a-belt-sander/

Best 4” x 36” Desktop Belt Disc Sander for Sale | VEVOR Abrasive Sanding Machine | 375W Grinding Polishing Power Tools

Best 4” x 36” Desktop Belt Disc Sander for Sale | VEVOR Abrasive Sanding Machine | 375W Grinding Polishing Power Tools